Hördener Holzwerk

Our Mission: A sustainable future – With high-quality products made in the black forest.

As part of the wood industry, we maintain a special relationship to a sustainable way of working, since sustainability is the foundation upon which our business is built. Without sustainable forestry, there would be no wood for us to work with, no wood that we could transform into high-quality timber. We see great potential in wood as a building material for generations to come.

Wood – A precious material for future generations

Wood is an exceptionally versatile material. It can be used as load bearing construction material of further processed to paper. Its different components can be extracted chemically to produce plastics that are free of fossil fuels or to produce clothes. All the time, new applications are discovered through innovative research, that enable us to use wood even more efficiently.

When processing wood, lots of saw dust and wood chips are created. In the past, these by-products were often referred to as “waste products”. However, this view has changed drastically during the past few years. Today, saw dust and wood chips are considered valuable resources. They are processed further, often becoming part of high-tech products, such as protectice cellulose layers for TV screens, to name only one example. This is good because it means wood can be used more efficiently. It also means that no additional trees have to be harvested since many products can now be made from these by-products.

The same applies to the construction sector. Wood products such as CLT (Cross Laminated Timber), Glulam (Glued Laminated Timber) and LVL (Laminated Veneer Lumber) are now capable of delivering incredible performances. All over the world, multistory buildings are being planned and built. This is the area in which wood can fully show its positive influence on slowing climate change. Inside it, large amounts of carbon are stored (up to 50 % of its mass). This carbon was once CO2 and was taken out of the air by the tree during photosynthesis. By using wood as a construcion material, this CO2 is stored and therefore withdrawn from the carbon cycle. To get a feeling of what this means: In a single m³ of spruce of average density, about 800 kg of potential CO2 are stored. Thousands of m³ are used in big construction projects.

When wood is burned up for generating energy, the carbon that was stored inside the wood is released and recombines with oxygen to form CO2, which is then emitted into the atmosphere. This process is considered to be climate neutral* and also happens when wood is decomposed naturally inside a forest. In the latter scenario organisms (especially fungi) are responsable for processing the carbon and for emitting CO2. Because of this, it is a fallacy to think, that left-alone woods are capable of permanently withdrawing atmospheric CO2 from the carbon cycle. This is only possible when wood is used as a construction material, e.g. inside buildings.

*The energetic use of wood can be considered climate neutral, since the CO2 emitted is the same which was extracted from the atmosphere by the tree during growth. This is different with fossil fuels which were stored inside the earth for sometims millions of years. When fossil fuels are burned, the atmosphere is burdened with “new” CO2 that had never been inside the atmosphere during human history.

Climate-neutral into the future

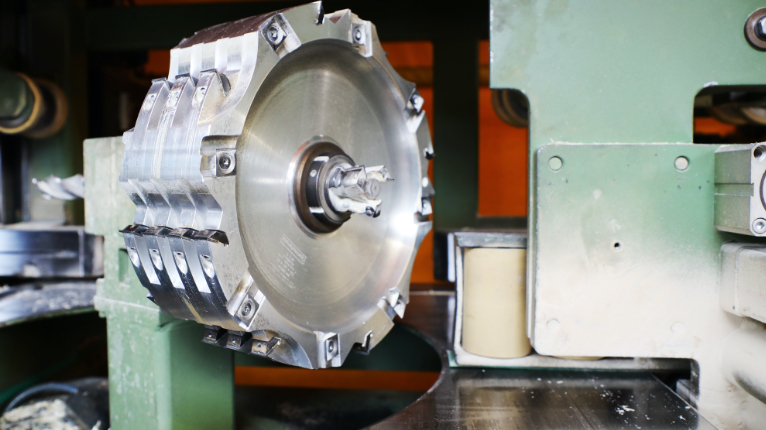

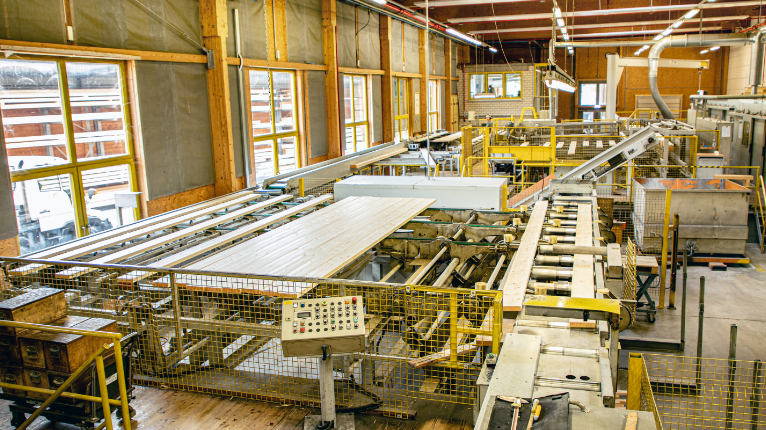

We are constantly working on reducing our influence on the environment by promoting innovation and by optimizing processes in all sections of our company. Our long-term goal is the establishment of a completely climate-neutral production, whose emissions will no longer need to be compensated by CO2-certificates.

We know that reaching climate-neutrality is an ambitious goal. In this goal, however, lies a great challenge. To reach our goal, we tread many different paths and try to continuously improve things withing our company. Besides the incremental expansion of our photovoltaic capacity and the electrification of our internal logistics, we also work on reducing consumable materials, e.g. paper or plastics. We have also implemented en energy management system according to DIN EN ISO 50001.

Since the beginning of 2022, we are part of the initiative “Klimaschutz Holzindustrie” (climate protecition initiative of the wood indutstry). We are among the first German glulam producers to join the initiative. As part of it, we had our carbon footprint calculated according to the internationally recognized GHG-Protocol. Based on our carbon footprint, further measures to reduce CO2-emissions can now be planned and implemented more precisely. From now on, all direct and indirect Co2-emissions (as well as other emissions that are usually converted into CO2-equivalents) that are emitted as a consequence of our company’s economic activities will be compensated by internationally recognized CO2-certificates originating from climate protection projects, such as a UN hydropower project in Myanmar and a forest protection project in Brazil.

As part of the initiative, we have committed ourselves to recalculate our carbon footprint at least once every to years as well as to continuously reduce all emissions in the long term. With our efforts, we hope to be able to contribute to the United Nation’s 1.5 °C gaol.

Find out more about the projects we support at